Mechanical Domain Fluctuations

Return to all Research Topics

Mechanical Domain Fluctuations

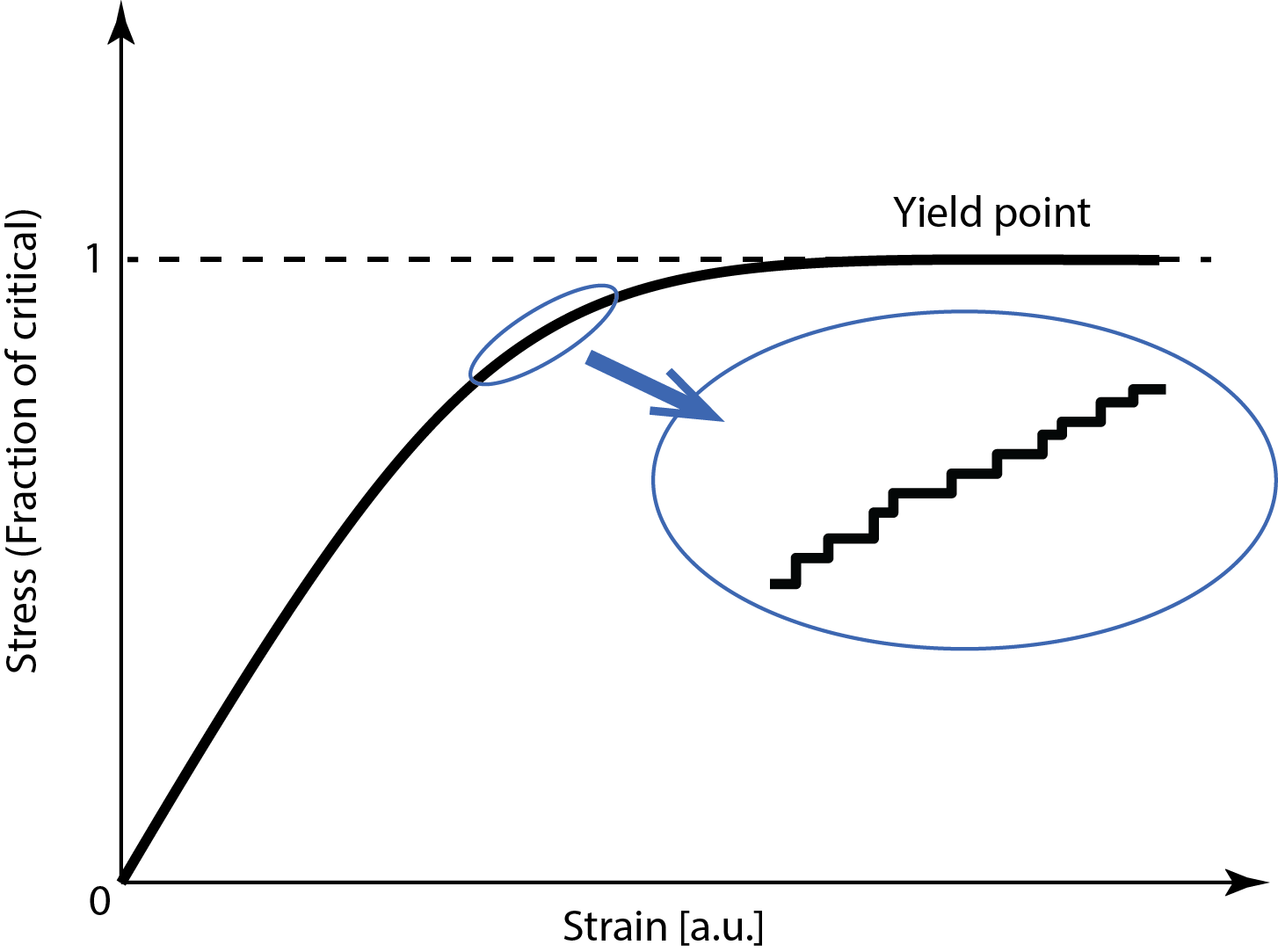

We have all been taught that most material deform elastically: the change in shape is smooth when we slowly increase the force we apply. This is only a very rough approximation. When you crumble a piece of paper, or when the wind shakes the trees in a forest, we can clearly hear sound at high frequency, while the crumbling and the wind provide only low frequency, slow, excitations. The reason for this is crackling noise: paper and wood, as well as most materials, respond to an external force in a series of discrete steps, of random sizes. The sum of all those small jumps can convert energy from the low frequency external excitation to the high frequency, audible range. The Advanced LIGO mirror are attached to complex seismic isolation systems, to provide isolation from the ground motion. Some components of the suspension system are cantilever springs made of steel. The goal of the Crackling Noise Experiment is to study the intensity and properties of crackling noise in steel, with a twofold goal: assess the level of noise we expect in Advanced LIGO, and better understand the microscopical foundation of mechanical non-linearities in metals far from the critical yielding point.

We have all been taught that most material deform elastically: the change in shape is smooth when we slowly increase the force we apply. This is only a very rough approximation. When you crumble a piece of paper, or when the wind shakes the trees in a forest, we can clearly hear sound at high frequency, while the crumbling and the wind provide only low frequency, slow, excitations. The reason for this is crackling noise: paper and wood, as well as most materials, respond to an external force in a series of discrete steps, of random sizes. The sum of all those small jumps can convert energy from the low frequency external excitation to the high frequency, audible range. The Advanced LIGO mirror are attached to complex seismic isolation systems, to provide isolation from the ground motion. Some components of the suspension system are cantilever springs made of steel. The goal of the Crackling Noise Experiment is to study the intensity and properties of crackling noise in steel, with a twofold goal: assess the level of noise we expect in Advanced LIGO, and better understand the microscopical foundation of mechanical non-linearities in metals far from the critical yielding point.

Publications

| JP Sethna, KA Dahmen, CR Meyers, "Crackling Noise", Nature 410, 242-250 (8 March 2001) | doi:10.1038/35065675 |

| EKH Salje, KA Dahmen, "Crackling noise in disordered materials", Annu. Rev. Condens. Matter Phys. (2014) |

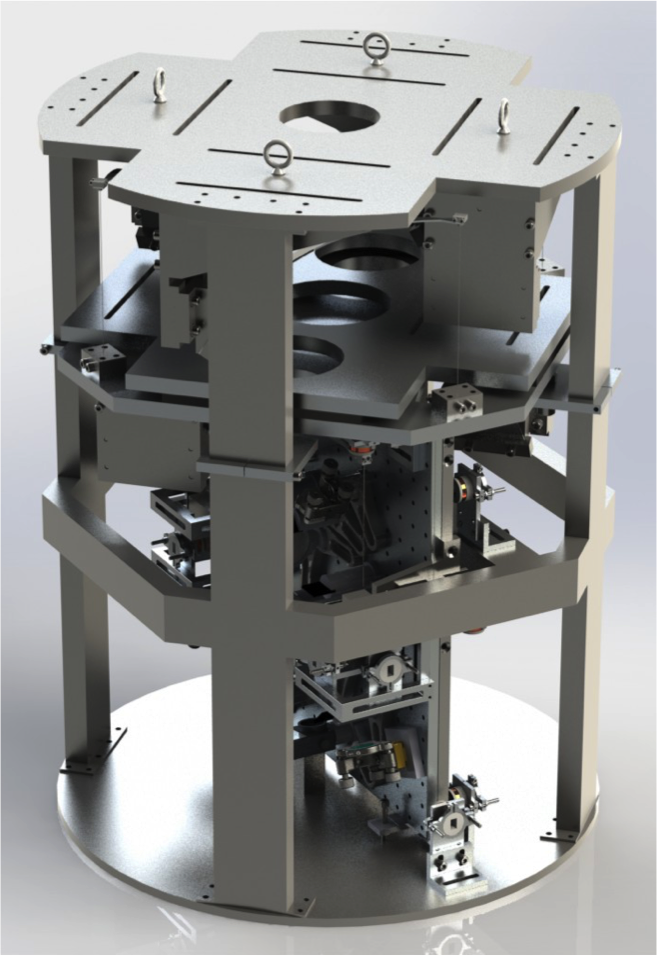

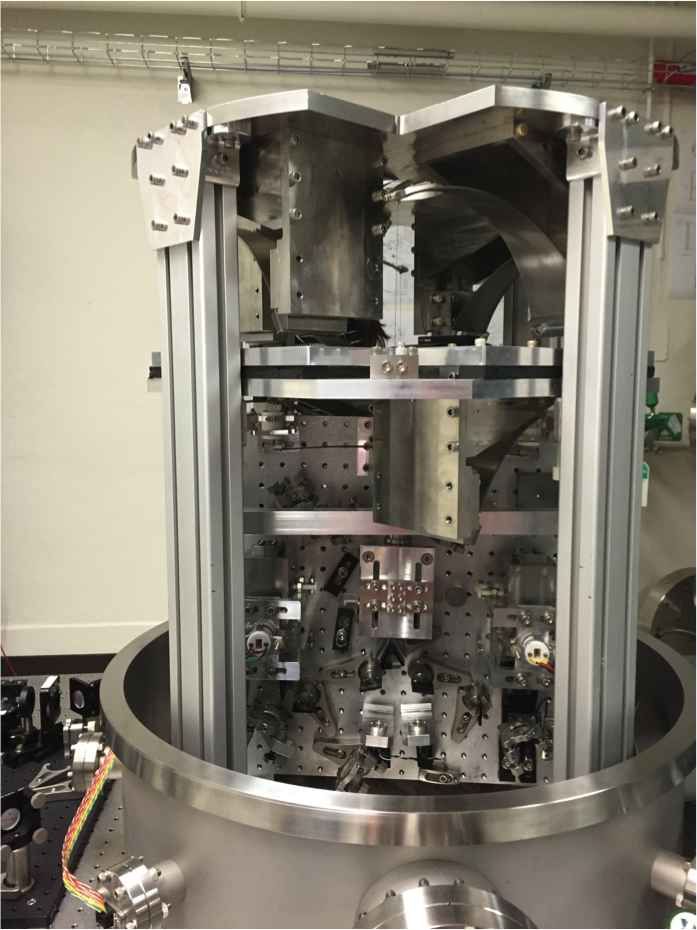

| G Vajente, EA Quintero, X Ni, et al. "An instrument to measure mechanical up-conversion phenomena in metals in the elastic regime", Rev. Sci. Inst. (2016) http://dx.doi.org/10.1063/1.4953114 |