Precision Optical Coatings & Scattering

Characterize and improve optical coating performance — scattering, absorption, and damage threshold — for gravitational-wave detectors, fusion cavities, and precision optical systems.

Gallery

Research area

Every mirror in a gravitational-wave detector scatters and absorbs a small fraction of the light that hits it. At LIGO’s circulating powers — hundreds of kilowatts in each arm cavity — even parts-per-million losses have consequences: scattered light creates noise, absorbed light distorts the mirror, and both limit sensitivity. We characterize and improve the optical coatings that control these losses.

The numbers that matter

Current LIGO mirrors achieve remarkable optical performance: absorption below 1 ppm, total scatter below 5 ppm, and surface roughness of ~0.1 nm RMS at 1064 nm. These coatings are deposited by ion beam sputtering (IBS) — alternating layers of SiO₂ (low index) and Ta₂O₅ (high index), each a fraction of a wavelength thick, building up to ~20 µm total thickness. The coatings are made by a small number of specialized vendors (primarily LMA Lyon and CSIRO) and characterized at Caltech and the LIGO sites before installation.

Even at these extraordinary specifications, optical losses limit detector performance. At 750 kW circulating power (the Advanced LIGO+ target), 0.5 ppm absorption deposits 375 mW into the mirror — enough to create thermal lensing that distorts the beam and degrades the interferometer’s mode matching. The adaptive optics system compensates for this, but reducing absorption at the source is more effective than correcting its consequences.

Scattering: where the light goes

Mirror surface roughness and coating defects scatter photons out of the main beam. Some of this light bounces off vacuum chamber walls and recombines with the main beam after picking up phase noise from vibrating surfaces — a process called backscatter noise. Other scattered light simply represents lost power, reducing the circulating field and degrading shot-noise-limited sensitivity.

We measure scattering using:

- Bidirectional reflectance distribution function (BRDF): Maps the angular distribution of scattered light at multiple wavelengths (1064 nm, 1550 nm, 2 µm). BRDF measurements distinguish between wide-angle scatter (from surface roughness) and near-specular scatter (from large-scale figure errors), which have different noise consequences in the interferometer.

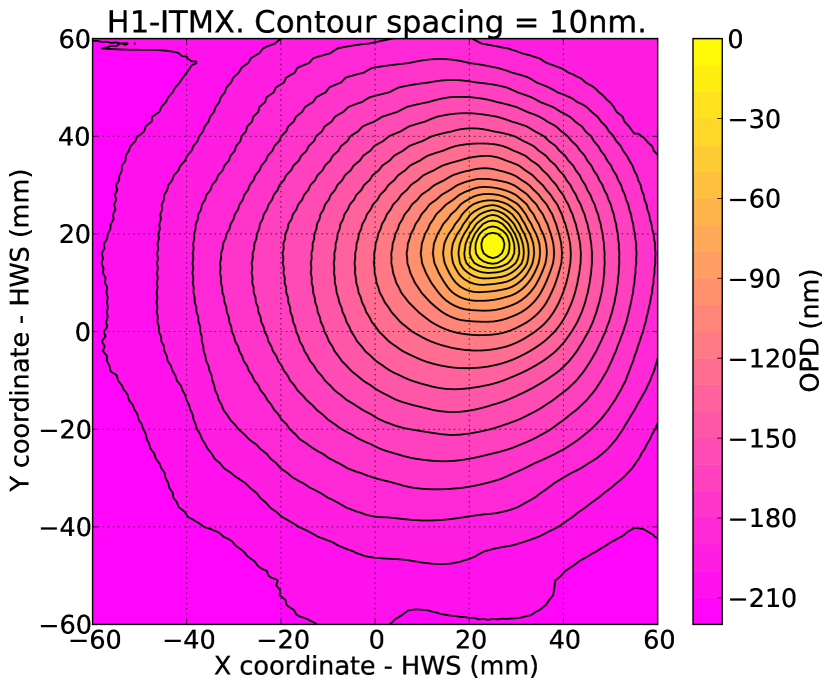

- Photothermal common-path interferometry: Detects absorption at sub-ppm levels by measuring the thermal lens created when a pump beam heats the coating. This technique maps absorption across the mirror surface with ~100 µm spatial resolution, revealing point absorbers — micron-scale coating defects with absorption up to 100× the bulk value.

- In-situ scattering monitors: Photodetectors installed at the LIGO sites that track scattered light levels over time, providing data on coating degradation during years of operation in ultra-high vacuum.

Point absorbers

Point absorbers are the single biggest optical coating problem in current LIGO detectors. These are localized defects — typically 10–30 µm in diameter — embedded in the coating stack during deposition. Each absorber acts as a microscopic heat source, creating a local thermal bump on the mirror surface that scatters light out of the fundamental Gaussian mode.

In Advanced LIGO, some mirrors have dozens of point absorbers, collectively limiting the usable circulating power. The physical origin is not fully understood: candidates include metallic contaminants from the deposition chamber, nodular defects from substrate particles, and intrinsic crystallization in the amorphous coating layers. Reducing their density requires improvements throughout the coating pipeline — cleaner substrates, better deposition chamber hygiene, and post-deposition inspection and rejection protocols.

How this differs from coating thermal noise

The Coating Thermal Noise project under the LIGO Infrastructure pillar focuses on the mechanical loss of coating materials — the internal friction that drives Brownian thermal noise in the mirror surface. That work is about the coating’s elastic properties and their impact on the detector noise budget.

This project focuses on the optical properties of coatings — scattering, absorption, damage threshold, and environmental degradation. The two are complementary: a coating with low mechanical loss but high scatter would still limit detector performance. The materials science overlaps (both projects deal with amorphous oxide thin films), but the measurement techniques and design optimization are distinct.

Applications beyond LIGO

High-performance optical coatings are enabling technology for:

- Optical enhancement cavities for fusion: The fusion cavity project needs mirrors that withstand MW-level circulating power without damage or degradation. Coating damage threshold and absorption are the key limiting factors — at MW/cm² intensities, even 0.1 ppm absorption creates thermal runaway.

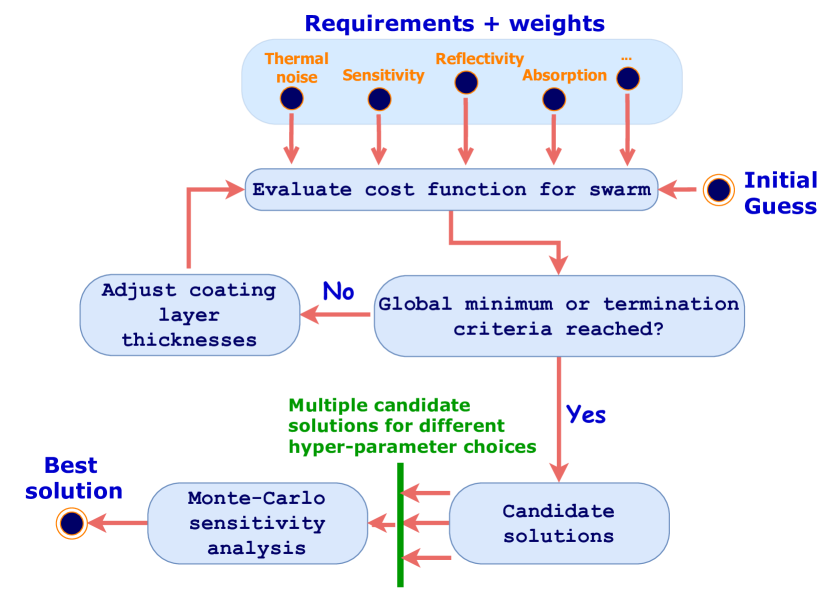

- Sum-frequency generation: The SFG cavity requires low-loss coatings at multiple wavelengths (1064 nm, 2050 nm, 700 nm) simultaneously — a challenging multi-band coating design problem where the layer structure must be optimized for reflectivity at three wavelengths.

- High-finesse reference cavities: Laser frequency stabilization cavities need the lowest possible scatter and absorption to achieve narrow linewidths. Cavities with finesse >500,000 require mirror losses below 3 ppm total.

Open questions

- Point absorber mitigation: Can improved IBS deposition techniques (plasma cleaning of substrates, better chamber vacuum, optimized deposition angles) reduce point absorber density to acceptable levels for A# and Cosmic Explorer? Or is a fundamentally different coating technology needed?

- Coatings at 2 µm: LIGO Voyager will operate at 2 µm on crystalline silicon substrates. The standard SiO₂/Ta₂O₅ coating stack must be redesigned — alternative materials (amorphous silicon, GaAs/AlGaAs crystalline coatings) have different scatter and absorption properties at this wavelength, and characterization infrastructure must be developed.

- Environmental degradation: LIGO mirrors operate in ultra-high vacuum for years. Monitoring data from Advanced LIGO suggests some coatings degrade over time — scatter increases, new point absorbers appear. Is this due to residual gas adsorption, radiation damage from the high-power laser, or mechanical stress from the coating stack? Long-term degradation data is essential for planning detector upgrades.

- High-damage-threshold coatings for fusion: Fusion enhancement cavities need coatings that survive MW/cm² intensities over billions of pulses. GW detector coatings are designed for CW operation; pulsed damage mechanisms (avalanche ionization, thermal shock) are qualitatively different and require distinct optimization.